Support at all stages of implementation

Quality control

The correctness of works and tests is supervised by our staff of the quality control department, whose competences have been confirmed by the most important units in Poland, including UDT-CERT, IS Gliwice.

Quality control is responsible for the proper conduct of tests and inspections in the scope indicated in the standards, regulations and technical specifications aimed at confirming that the device has been manufactured, modernized or repaired correctly and does not pose any threats during proper operation, in accordance with the instructions.

Basic quality control activities include:

1. Performing visual examinations using the direct method, e.g. weld gauges, callipers, etc. as well as an indirect one using a video endoscope.

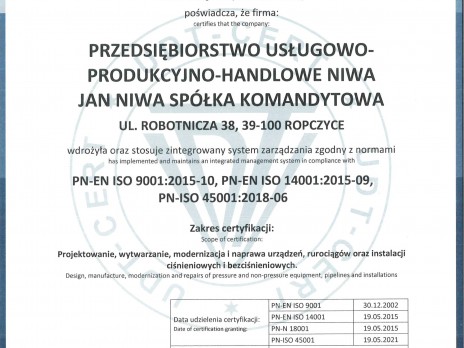

ISO 9001, 14001:2015, 45001

NIWA has implemented an Integrated Management System, which consists of three complementary and interacting standards:

- PN-EN ISO 9001:2015 Quality Management System

- PN-EN ISO 14001:2015 Environmental Management System

- PN-ISO 45001 Occupational Health and Safety Management System

Thanks to these standards, we guarantee that all of our services and products are delivered at the highest quality as well as care for the natural environment and safety in the workplace.

Familiarise yourself with our Integrated Management System Policy – download the flyer here.

2. Conducting penetration tests using ready-made detecting preparations, i.e. remover, penetrant, developer from reputable suppliers.

ISO 9001, 14001:2015, 45001

NIWA has implemented an Integrated Management System, which consists of three complementary and interacting standards:

- PN-EN ISO 9001:2015 Quality Management System

- PN-EN ISO 14001:2015 Environmental Management System

- PN-ISO 45001 Occupational Health and Safety Management System

Thanks to these standards, we guarantee that all of our services and products are delivered at the highest quality as well as care for the natural environment and safety in the workplace.

Familiarise yourself with our Integrated Management System Policy – download the flyer here.

3. Performing other destructive and non-destructive tests, identification of materials in cooperation with qualified laboratories.

ISO 9001, 14001:2015, 45001

NIWA has implemented an Integrated Management System, which consists of three complementary and interacting standards:

- PN-EN ISO 9001:2015 Quality Management System

- PN-EN ISO 14001:2015 Environmental Management System

- PN-ISO 45001 Occupational Health and Safety Management System

Thanks to these standards, we guarantee that all of our services and products are delivered at the highest quality as well as care for the natural environment and safety in the workplace.

Familiarise yourself with our Integrated Management System Policy – download the flyer here.

4. Measurements of surface roughness after grinding, after abrasive blasting, flange faces.

ISO 9001, 14001:2015, 45001

NIWA has implemented an Integrated Management System, which consists of three complementary and interacting standards:

- PN-EN ISO 9001:2015 Quality Management System

- PN-EN ISO 14001:2015 Environmental Management System

- PN-ISO 45001 Occupational Health and Safety Management System

Thanks to these standards, we guarantee that all of our services and products are delivered at the highest quality as well as care for the natural environment and safety in the workplace.

Familiarise yourself with our Integrated Management System Policy – download the flyer here.

5. Performing basic measurements of flatness, straightness, circularity, ovality, shape.

6. Checking the degree of corrosion before cleaning and the degree of surface preparation before anti-corrosion protection.

7. Measurements of the thickness of anti-corrosion protection.

8. Ultrasonic measurement of material thickness.

ISO 9001, 14001:2015, 45001

NIWA has implemented an Integrated Management System, which consists of three complementary and interacting standards:

- PN-EN ISO 9001:2015 Quality Management System

- PN-EN ISO 14001:2015 Environmental Management System

- PN-ISO 45001 Occupational Health and Safety Management System

Thanks to these standards, we guarantee that all of our services and products are delivered at the highest quality as well as care for the natural environment and safety in the workplace.

Familiarise yourself with our Integrated Management System Policy – download the flyer here.

9. Performing hydraulic pressure tests.

ISO 9001, 14001:2015, 45001

NIWA has implemented an Integrated Management System, which consists of three complementary and interacting standards:

- PN-EN ISO 9001:2015 Quality Management System

- PN-EN ISO 14001:2015 Environmental Management System

- PN-ISO 45001 Occupational Health and Safety Management System

Thanks to these standards, we guarantee that all of our services and products are delivered at the highest quality as well as care for the natural environment and safety in the workplace.

Familiarise yourself with our Integrated Management System Policy – download the flyer here.

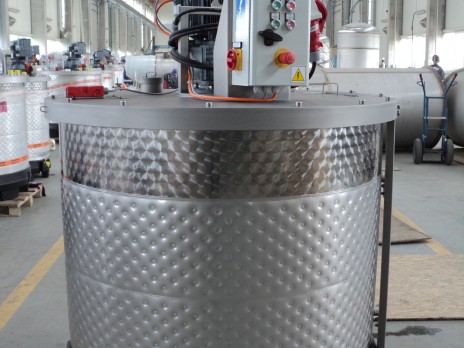

10. Performing functional tests involving, among others, on the control of the operation of the device with a stirrer.

ISO 9001, 14001:2015, 45001

NIWA has implemented an Integrated Management System, which consists of three complementary and interacting standards:

- PN-EN ISO 9001:2015 Quality Management System

- PN-EN ISO 14001:2015 Environmental Management System

- PN-ISO 45001 Occupational Health and Safety Management System

Thanks to these standards, we guarantee that all of our services and products are delivered at the highest quality as well as care for the natural environment and safety in the workplace.

Familiarise yourself with our Integrated Management System Policy – download the flyer here.