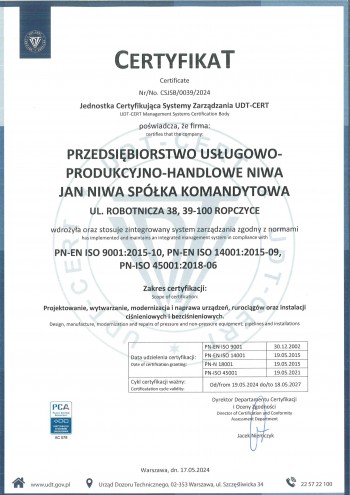

ISO 9001, 14001:2015, 45001

NIWA has implemented an Integrated Management System, which consists of three complementary and interacting standards:

- PN-EN ISO 9001:2015 Quality Management System

- PN-EN ISO 14001:2015 Environmental Management System

- PN-ISO 45001 Occupational Health and Safety Management System

Thanks to these standards, we guarantee that all of our services and products are delivered at the highest quality as well as care for the natural environment and safety in the workplace.

Familiarise yourself with our Integrated Management System Policy – download the flyer here.

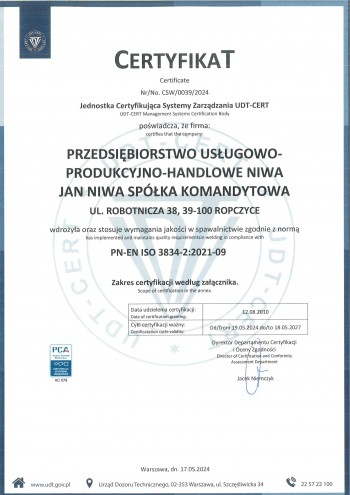

Certificate 3834:2

The PN-EN ISO 3834 certificate is an objective proof that the welding processes done in the NIWA company are carried out in an effective manner, and the supervision over manufactured products is performed at all stages of such process.

At each stage of production, NIWA provides the supervision of experienced welding engineers (IWE) and certified quality controllers with the qualifications of non-destructive testing (NDT). Certification of welders are provided on the basis of the PN-EN ISO 9606 standard.

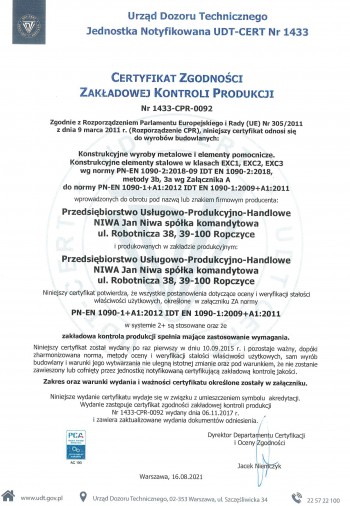

PED 2014/68/UE

All over the world, pressure equipment is subject to strict regulations.

As a manufacturer of devices, we ensure compliance with the requirements of the PED 2014/68 /EU directive, according to SEP, module A, module A2, B+F modules, module G.

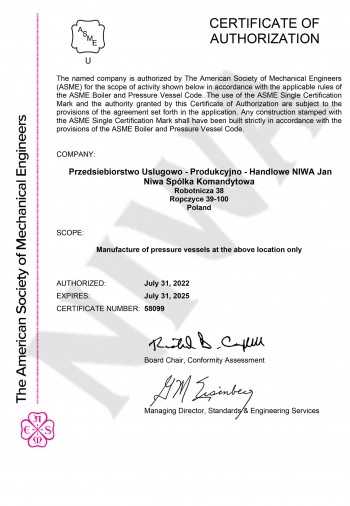

ASME-U

We have an authorization certificate to manufacture pressure equipment on our workshop issued by one of the world's most recognizable standardization organizations, i.e. the American Society of Mechanical Engineers. Our staff has experience and is properly trained and certified to design and supervise designing and supervision of welding processes and NDE tests (external laboratory). Each device leaving the facility is inspected by an independent authorized LRQA inspector and carries an ASME stamped company nameplate with U designator.

In accordance with ASME policy, the certificate is provided for informational purposes and may not be processed in any way without the written consent of NIWA.

MQC

Manufacturing Quality Control, approved with accordance to the EN 1090 standard is a system necessary for the conformity assessment of steel structures and for placing them on the European market. It means constant internal production control that is carried out by the manufacturer at every stage of the fabricated structure. Meeting the requirements contained in the EN 1090 standard ensures manufacturing stability and obtaining product features in accordance with the technical specifications.